The year is 2020. Technology and knowledge have advanced farther than ever before. We’ve walked on the moon and pioneered electric vehicles. Utilized the most advanced technologies available to develop powerful artificial intelligence (AI) and continuously generate tremendous amounts of data in hopes of growing our knowledge of the world further still. And created plastics that can degrade in the natural environment… or have we?

Understanding Bioplastics

There are several advanced bioplastics readily available today, and while the idea of a truly “degradable” plastic (which can effectively break down in any environment – soil, marine, etc.) is desirable, the reality of bioplastics is much more complex. Before we can understand the dangers of “degradable” plastics we must first deepen our understanding of bioplastics.

What are Bioplastics?

Biobased vs. Compostable

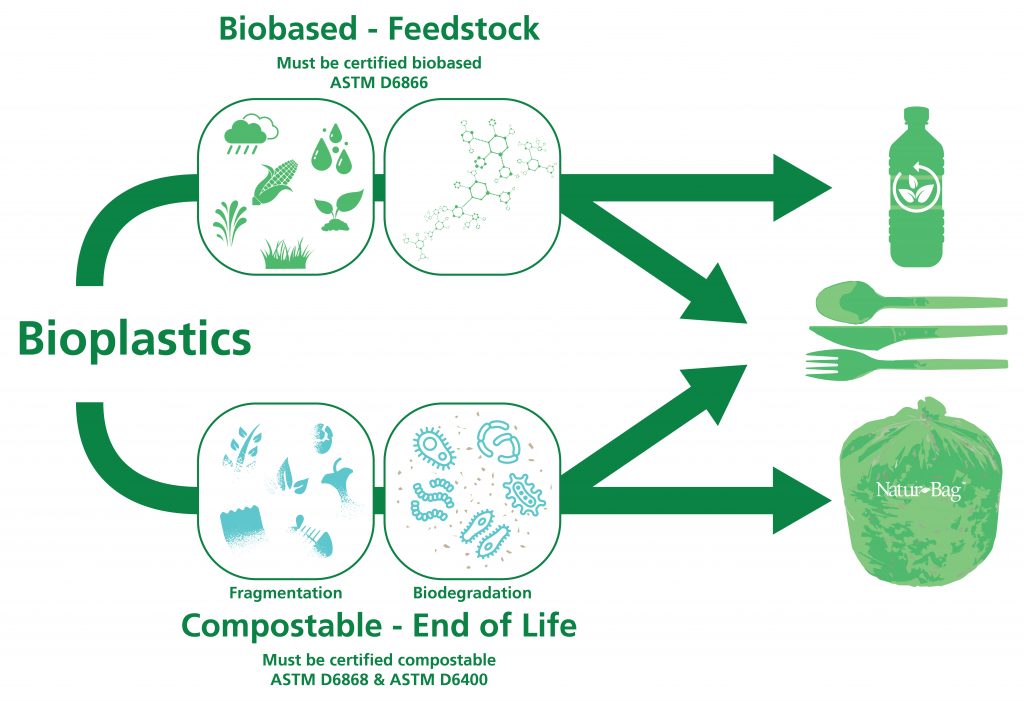

So, what exactly are “bioplastics”? Bioplastics offer two distinct value propositions: biobased and compostable – some applications are both biobased and compostable.

Compostable plastics can be broken down by natural processes and release the carbon contained in the original material through the processes of microbial assimilation. Biobased plastics are made from sustainable renewable materials such as corn and sugarcane.

What is Biodegradation?

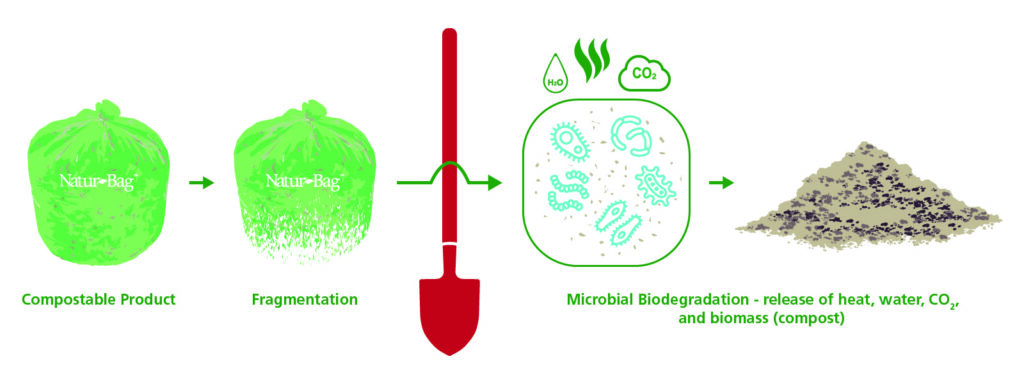

Biodegradation is the breakdown of organic matter by microorganisms in the environment. This process begins with fragmentation and is completed through microbial processes which repurpose the carbon. There is no universal scientific definition for biodegradation that specifies the environment and duration of the process.

Composting is an actively managed process, that defines both the environment and duration for the process (in an industrial composting facility, in less than 180 days, the same rate as natural materials – such as leaves and grass clippings). Certified compostable products are engineered to not disrupt the composting process. As microbes break down these and other organic materials, heat, water, carbon dioxide, and biomass are released and no plastic is left behind. Compostable plastics are strictly regulated by widely accepted international standards such as ASTM D6400 and EN 13432. Note that these are standards – NOT test methods. Standards are pass/fail and ensure that a material meets or exceeds the requirements necessary to ensure compostability under defined conditions, environment, etc. More on standards and test methods later…

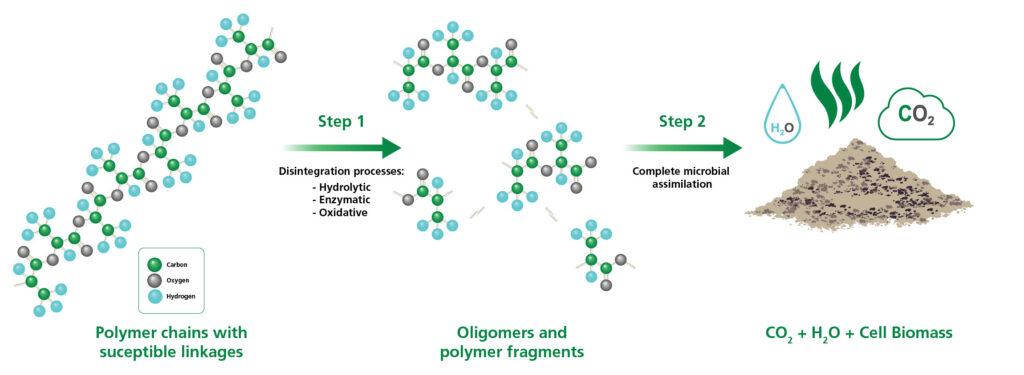

Why Bioplastics Biodegrade

Certified compostable plastics are engineered such that the polymer chains are susceptible to degradation through the hydrolytic, oxidative, or enzymatic disintegration processes. Once the polymer chains have been broken, microbes consume the fragmented residues as a food and energy source and release carbon dioxide, water, and cell biomass.

Standards vs. Test Methods

Before we discuss the dangers of so called “degradable” plastics, it is important to understand the difference between ASTM standards and ASTM test methods. For the sake of explanation, we’ll present both standards and test methods as they relate to compostable plastics.

Standards ensure a product or material is compliant with the defined criteria for compostable plastics (ex. ASTM D6400 which ensures compostability).

Test methods are defined means of testing a product or material which produce results.

See below for official definitions provided by ASTM International.

standard, n—as used in ASTM International, a document that has been developed and established within the consensus principles of the Society and that meets the approval requirements of ASTM procedures and regulations. DISCUSSION—The term “standard” serves in ASTM International as a nominative adjective in the title of documents, such as test methods or specifications, to connote specified consensus and approval. The various types of standard documents are based on the needs and usages as prescribed by the technical committees of the Society.

test method, n—a definitive procedure that produces a test result. DISCUSSION—Examples of test methods include, but are not limited to: identification, measurement, and evaluation of one or more qualities, characteristics, or properties. A precision and bias statement shall be reported at the end of a test method.

The Dangers of Oxo-degradable Plastics

“Oxo-Degradable”, “Oxo-Biodegradable”, etc.

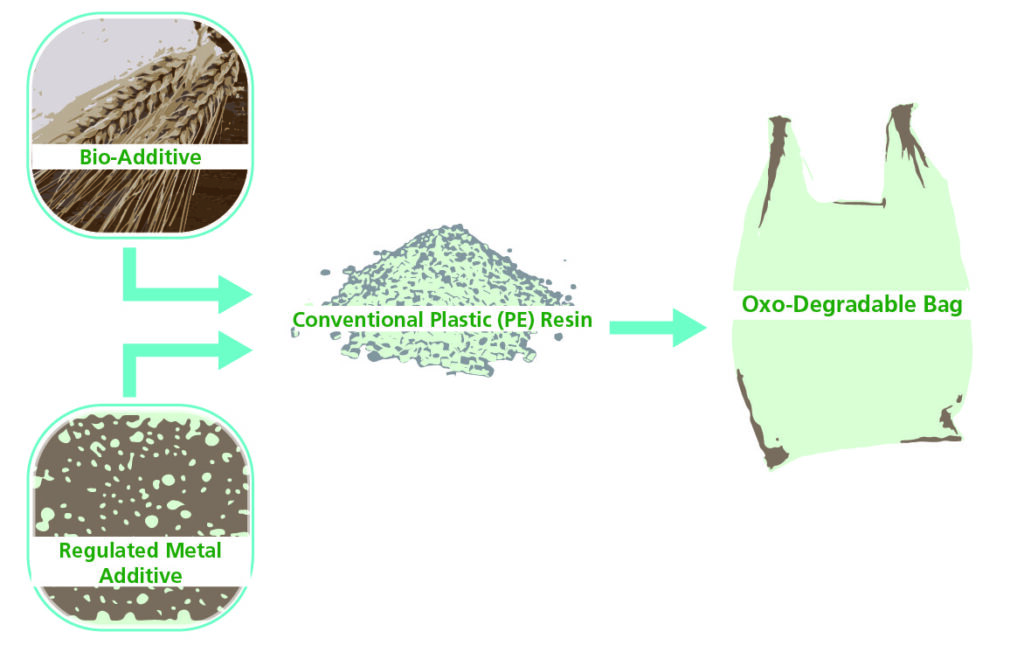

In both film and molded plastic applications, there are additive technologies where bio-additives (such as starch) are added to traditional plastic (such as PP, PE, PS, etc.) and falsely marketed as compostable and/or biodegradable. These oxo-degradable products are often more damaging to the environment than traditional plastic!

Often, these technologies reference meeting ASTM 5511 or ASTM 5526. These are not standards, rather they are test methods used to extrapolate biodegradation rates in anaerobic environments (such as landfills). While some materials partially biodegrade in a landfill (or other anaerobic settings), the biodegradation observed is only partial and releases methane (which is 23x more potent than carbon dioxide).

Disposal of “Degradable” and Traditional Plastics…

Some products made from traditional plastic are effectively recycled (polypropylene, polystyrene, PET, etc.). When proper infrastructure and collection methods are available, recycling is the best end-of-life option for these materials. Since oxo-degradable products often replace hard or impossible to recycle products and contain additives, they are not recyclable. When recycling is not an option, these materials should be disposed of in a properly controlled landfill which will significantly limit the ability of leakage and pollution resulting from degrading plastics.

Traditional plastics such as PP (polypropylene), PS (polystyrene), and PE (polyethylene), are made from strong carbon to carbon bonds. These bonds require extremely long periods of time to break down on their own. Truly compostable materials, when disposed of in an industrial composting facility, repurpose the carbon in organics and other materials and release it as carbon dioxide as the composting process takes place. This released CO2 is then fixed by plants and crops as part of the natural carbon cycle.

The Reality of Plastics and the Environment…

Oxo-degradable products are often falsely marketed as being biodegradable, when they are only partially degradable. These materials are prohibited by law in CA, WA, MN, and MD. Since these products are in fact made from traditional plastics, they break down (degrade) over time. This is often referred to as “fragmentation”, as large pieces of material break down into subsequently smaller pieces eventually resulting in micro-plastics. These small plastic particles easily enter and move throughout the environment harming ecosystems and wildlife alike.

Today, micro-plastics are present in every major body of water on earth (it is estimated there are currently 12.5 – 125 trillion particles in the world’s oceans… a number which will only increase with time as ever present plastic pollution continues to fragment over time). Worse yet, recent studies have detected micro-plastics are present in 90% of table salt, and even in the air we breathe.

Plastics and the Future

So, where do we go from here? There is a clear need for sustainable alternatives to conventional plastics, and an even greater need to reduce overall consumption of single-use plastic products and ensure the plastics of tomorrow integrate within the Circular Economy.

In order to effectively address these challenges, we must hold plastics to a higher standard and make certain biodegradable plastics are managed effectively and degradable plastics become a distant memory of a less sustainable past.

Sustainability, For All

A truly sustainable future is only possible through shared advances in technology and knowledge. Together we can continue to develop innovative solutions to the challenges surrounding plastics and the environment and create a better future for ourselves, and for those yet to come.